Industrial Valves

For many years, responding to our customers’ needs we supply many types of valves together with our hose assemblies. Thanks to this long cooperation with the valve manufacturers we offer specialized valves designed for different types of industrial installations.

TICON is supplying industrial valves for different industrial sectors. We share our experience of selecting the products suited to the needs, requirements, norms, fluid characteristics and environment. Every valve is supplied with the required documentation.

![]()

Parameters:

To find out which valve is suitable for the specific application the classical features and parameters must be observed:

- chemical resistance – following the medium (fluid) characteristics the main construction parts and seals material have to be selected. Commonly available body materials are: carbon steel, stainless steel, PVC and PP,

- working pressure range,

- working temperature range,

- nominal diameter DN,

- installation gap / space,

- actuation type: manual (handle, lever, gear) / electric / pneumatic/electrohydraulic actuator.

![]()

Additional parameters:

- connection type according to the norm (EN 1092-1, ANSI B16.5):

- flange (version of butterfly valve: wafer or LUG type),

- tweld end (butt weld, socked weld),

- thread (BSP, NPT, DIN 11851, SMS, etc. male or female).

- additional construction requirements:

- for ball valves (Full Flow, DPE, Trunnion Ball, Fire-Safe, DBB etc.),

- for shut-off valves type of stem,

- for butterfly valves construction style (concentric, doubly-eccentric or triply –eccentric),

- o for gate valves (construction types referring to closures: wedge, double disc, knife; or referring to the rising mechanism: with rising stem or non-rising).

Ball Valves

![]() This is the type of valve, where the shutting element is a hollowed ball bore or a piece of ball.

This is the type of valve, where the shutting element is a hollowed ball bore or a piece of ball.

Ball valves are designed to fully open or close the flow of fluid in the pipeline. They are widely used in water supply, power plants, paper mills as well as in chemical, petrochemical industries and for cryogenics.

Ball valve design features:

Floating Ball Valves with compensation:

In the floating ball compensated design the ball sealing is provided by double beveled seal: one seal is permanently fixed in the valve body and the second is fixed in the spring supported moving seat ring.

When pressure is applied form the moving ring side both seals performs sealing function. For low pressures the tightness is achieved due to springs. When the pressure is growing, the pressure itself ensure the tightness.

![]()

In case when the pressure is applied from the seal fixed in the body side, the tightness in low pressures is provided by both seals. When pressure grows, the ball is being moved and then the tightness is kept thanks to the seal fixed in the moving ring.

![]()

The design of compensated ball valve with floating ball don’t let to grow the pressure in the space between the body and the ball, when working with the liquid, and eliminates stress due to the temperature changes.

Drainage (venting) system

DBB (Double Block and bleed)

![]()

DBB system allows to release the pressure kept from the space between the ball and the body, regardless if the valve is in the open or in the closed position. This enables to check the valve tightness without disassembling. Pressure is released form the body by unscrewing the drain plug.

Lubrication and cleaning

![]()

During their operation, the ball valves wear out, which could be observed as wear and scratches of seal and the ball. These defects can be regenerated by system of applying special, high-viscous grease to the area where the seal is touching the ball.

The ball valves with lubricating system are not filled with the lubricating grease

PMSS-„Primary Metal Secondary Soft” Sealing System

![]()

This type of sealing system – PMSS – is dedicated for gaseous media. The first seal is achieved with special metal surface, the second is polymer or elastomer seal that guarantee the valve tightness.

Fire Safe Design

![]() Fire safe design is based on the special sealing elements, made of metal and graphite, which help to keep tightness in case of fire, according to the requirements of specific norms. Fire safe design is available as an option, supplied upon request.

Fire safe design is based on the special sealing elements, made of metal and graphite, which help to keep tightness in case of fire, according to the requirements of specific norms. Fire safe design is available as an option, supplied upon request.

Butterfly Valves

![]()

Butterfly valves are designed to open or shut-off the flow. It can be used to regulate the flow, but in this case, especially when they are used in this mode longer 100% tightness cannot be guaranteed.

According to the style of assembly they are usually met in the installations in one of the three above mentioned forms.

Concentric butterfly valves

Closing the valve is achieved by rotating the disc assembled on the rod. The sealing element is the seal. In the most of designs met on the market seals are profiled in the way that the additional flat seals for the pipeline flanges are not necessary. They can be on-vulcanized or replaceable.

Combination of the materials used for the specific parts of the butterfly valves like body, rod, disc and seal are different, depending on the designed working parameters and medium. For the aggressive media mostly used is PVC-U or PP, for very aggressive – Duroplastic material coated with TFM or PFA.

Butterfly valves, aside from the basic types with concentric disc positioning, may have more advanced designs providing eccentric disc placement thus bring an extra advantages.

Single offset design:

Single cam

Single cam

- rotating rod axis is offset from the centerline of the body seat seal

- oś wału sterowniczego obok osi uszczelki

The disc is fixed to the actuating rod and the spigot which are rotating in self-lubricating bearings.

![]()

Double Offset design.

Double Offset design

- rotating rod axis is offset from the centerline of the body seat seal,

- rotating rod axis is offset from the centerline of the bore.

![]()

Triple offset design.

Triple offset design

- rotating rod axis is offset from the centerline of the body seat seal

- rotating rod axis is offset from the centerline of the bore

- sealing seat cone axis is offset from the bore axis

![]()

The triple cam design assure, that except from the fully closed position the seat seal is not touching the disc sealing surface This increases the lifetime of the seal and number of operations.

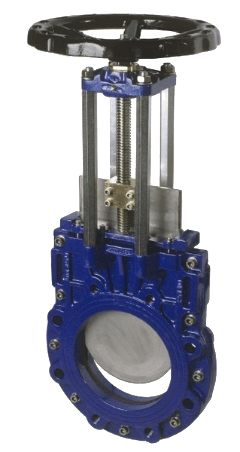

Gate Valves

Gate Valves

Gate valves are typically shut-off types – designed to fully open or close the flow of the medium. For flow control operations we suggest special designs.

Gate valves have many designs. Except from the basic ones, there are also designs providing additional advantages, different stem solutions (rising vs. non-rising) and forms of closures (wedge types).

Types of gate valves – examples

Gate valve with rising stem.

Body, bonnet: casting

Flexible wedge

Gate valve with rising stem.

Body, bonnet: casting

Rigid wedge

With bonnet and non-rising stem